Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

Estimated lead times

1 Day

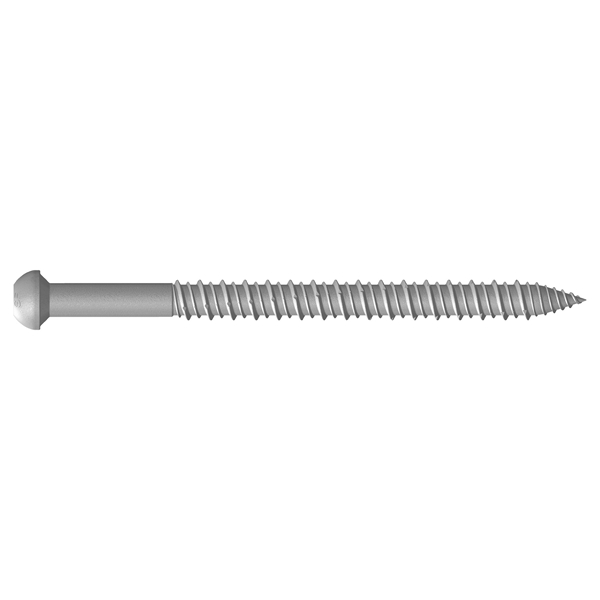

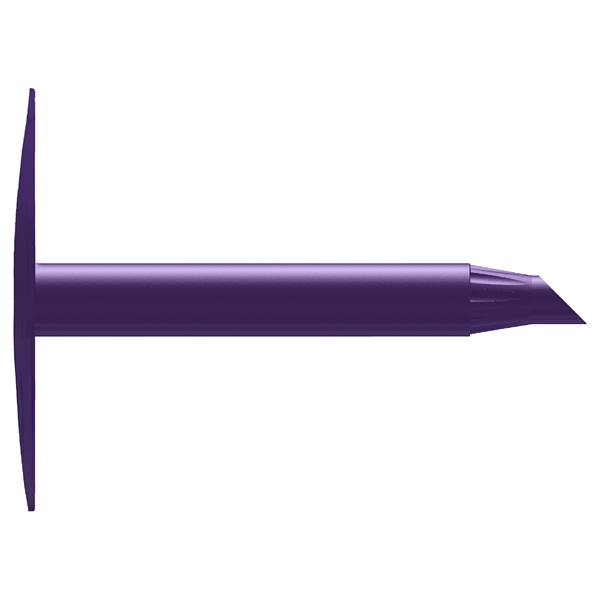

Carbon steel fasteners for fixing to concrete, timber and some steel decks.

Can be combined with SureFast® tube washers and pressure plates to suit insulation and membrane applications.

- Specially designed thread formation for use with concrete and timber substrates

- Excellent performance and resistance to unwinding

- ETA Approval and CE Marked

- UKTA Approval and UKCA Marked

- CCPI verified

- Purpose-designed and precision manufactured by Fixfast

- For mechanically fixing single-ply and flat roofing systems to concrete decks in combination with appropriate SureFast® components

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| Installation tool | Variable speed electric screw gun |

| Installation drive | TX25 |

| Installation speed | 1500 RPM |

| Correct installation | Fasteners should be driven within three degrees of perpendicular to the surface of the fastened material. Use a depth-setting nosepiece to avoid over-driving, and do not over-tighten. Variants with bonded washers should not have the rubber compressed to less than two-thirds of its uncompressed height. Care should be taken when engaging and disengaging from the fastener head to avoid damage to the protective coating. |

| Handling | Fasteners may have sharp edges, and the use of power tools can be dangerous. Use personal protective equipment. Store fasteners in dry conditions. Inspect each fastener before use and do not use damaged fasteners. |

Carbon steel fasteners for fixing to concrete, timber and some steel decks.

Can be combined with SureFast® tube washers and pressure plates to suit insulation and membrane applications.

- Specially designed thread formation for use with concrete and timber substrates

- Excellent performance and resistance to unwinding

- ETA Approval and CE Marked

- UKTA Approval and UKCA Marked

- CCPI verified

- Purpose-designed and precision manufactured by Fixfast

- For mechanically fixing single-ply and flat roofing systems to concrete decks in combination with appropriate SureFast® components

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| NR,II,K (Tensile - Pull-out) | 18mm Plywood: 2.07 kN |

| 0.7mm Steel: 1.16 kN | |

| Concrete C32/40 25mm Embedment: 1.98 kN |

| Installation tool | Variable speed electric screw gun |

| Installation drive | TX25 |

| Installation speed | 1500 RPM |

| Correct installation | Fasteners should be driven within three degrees of perpendicular to the surface of the fastened material. Use a depth-setting nosepiece to avoid over-driving, and do not over-tighten. Variants with bonded washers should not have the rubber compressed to less than two-thirds of its uncompressed height. Care should be taken when engaging and disengaging from the fastener head to avoid damage to the protective coating. |

| Handling | Fasteners may have sharp edges, and the use of power tools can be dangerous. Use personal protective equipment. Store fasteners in dry conditions. Inspect each fastener before use and do not use damaged fasteners. |

Client Technical Services

Fixfast's technical team provides a range of calculations and technical services to contractors and architects looking to purchase or specify our products. You can find out more about these services here, or register a request below.

On site support

On site support

Book a visit to your project by one of our technical consultants. Every visit will be followed up with a comprehensive written report to ensure you have all the information you need.

Tapered scheme fastener selection

Tapered scheme fastener selection

Upload a plan for your tapered insulation scheme, and we’ll calculate the optimum fastener requirements for each insulation board thickness.

Wind load calculation

Wind load calculation

Windload calculations typically for flat roofing projects using our SureFast flat roofing fastener systems, in accordance with BS EN 1991-1-4:2005 +A1:2010.