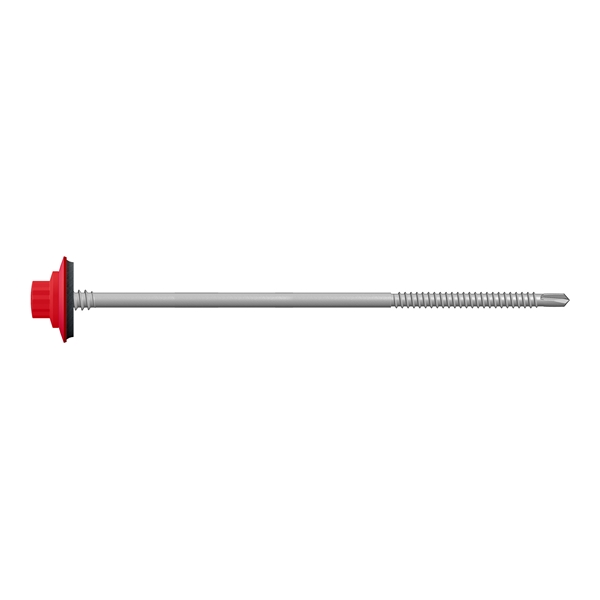

A4/316 grade stainless steel stitching fasteners supplied pre-assembled with an aluminium backed EPDM 19mm diameter sealing washer. For use in multiple systems roofing and cladding systems such as Rooflights and Rainscreen Facade sub-framing systems

Estimated lead times

1 Day

Estimated lead times

1 Day

A4/316 Stainless steel stitching fastener for clamping together multiple layers of materials.

- High pull-out performance

- A4/316 grade stainless steel fastener (EN1.4401)

- Free spin zone prevents fasteners from being over driven

- Supplied pre-assembled with a conical aluminium backed thick soft EPDM 19mm diameter sealing washer

|

Years / Environment

|

|||||||

|---|---|---|---|---|---|---|---|

| Interior | Semi-interior | Rural | Urban | Industrial / Coastal | Marine | Swimming pools & Chemical plants | |

| Corrosivity Category | C1 | - | C2 | C3 | C4 | C5 | - |

| Austenitic Stainless Steel A4 Grade (316) | 40 | 40 | 40 | 40 | 30 | 25 | 0 |

| NR,II,K (Tensile - Pull-out) | 0.7mm Steel: 1.58 kN |

| Installation tool | Variable speed electric screw gun |

| Installation drive | Fixfast GreenDrive (8mm hex integral socket with retaining clip) |

| Installation speed | 1500 RPM |

| Correct installation | Fasteners should be driven within three degrees of perpendicular to the surface of the fastened material. Use a depth-setting nosepiece to avoid over-driving, and do not over-tighten. Variants with bonded washers should not have the rubber compressed to less than two-thirds of its uncompressed height. Care should be taken when engaging and disengaging from the fastener head to avoid damage to the protective coating. |

| Handling | Fasteners may have sharp edges, and the use of power tools can be dangerous. Use personal protective equipment. Store fasteners in dry conditions. Inspect each fastener before use and do not use damaged fasteners. |

A4/316 Stainless steel stitching fastener for clamping together multiple layers of materials.

- High pull-out performance

- A4/316 grade stainless steel fastener (EN1.4401)

- Free spin zone prevents fasteners from being over driven

- Supplied pre-assembled with a conical aluminium backed thick soft EPDM 19mm diameter sealing washer

|

Years / Environment

|

|||||||

|---|---|---|---|---|---|---|---|

| Interior | Semi-interior | Rural | Urban | Industrial / Coastal | Marine | Swimming pools & Chemical plants | |

| Corrosivity Category | C1 | - | C2 | C3 | C4 | C5 | - |

| Austenitic Stainless Steel A4 Grade (316) | 40 | 40 | 40 | 40 | 30 | 25 | 0 |

| NR,II,K (Tensile - Pull-out) | 0.7mm Steel: 1.58 kN |

| Installation tool | Variable speed electric screw gun |

| Installation drive | Fixfast GreenDrive (8mm hex integral socket with retaining clip) |

| Installation speed | 1500 RPM |

| Correct installation | Fasteners should be driven within three degrees of perpendicular to the surface of the fastened material. Use a depth-setting nosepiece to avoid over-driving, and do not over-tighten. Variants with bonded washers should not have the rubber compressed to less than two-thirds of its uncompressed height. Care should be taken when engaging and disengaging from the fastener head to avoid damage to the protective coating. |

| Handling | Fasteners may have sharp edges, and the use of power tools can be dangerous. Use personal protective equipment. Store fasteners in dry conditions. Inspect each fastener before use and do not use damaged fasteners. |